RepliSLS3D

is an integrated solution for nearly all kinds of

3D printing, laser sintering (SLS/SLM), additive

manufacturing, stereolithography (SLA) and other

rapid prototyping applications.

RepliSLS3D is not only a simple slicer but a fully equipped software which is able to control the complete buildprocess including full access to all hardware

components needed for operating a 3D printer and also including control of several process parameters like temperature, gas pressure or concentration. So RepliSLS

incorporates all the functions needed for 3D printing into one software package:

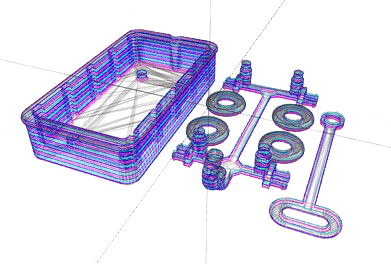

- import of 3D data using several formats

- slicing of these 3D models

- optional creation of support structures

- processing of the sliced layers including full laser and scanner hardware control

- handling all movements and operations between layers for material provision, z-movement and others

- controlling of additional process parameters such as pressure, gas concentration, temperature,...

It supports a lot of different hardware from scratch,

provides several features which are not common to

this kind of software and supports Windows™ and

Linux™.

It is available as software-only solution as well as

an integrated package which comes with suitable

controller hardware for a fast, easy and an as

uncomplicated as possible set-up of a new system.

RepliSLS3D is intended to be used for machine

integration, it can be customised in several ways to

fit to a specific machine type, its hardware and

functionalities. And it of course also can be branded

so that the whole software comes with a customer-specific name which fits to the machine and no

longer uses the generic name "RepliSLS3D".